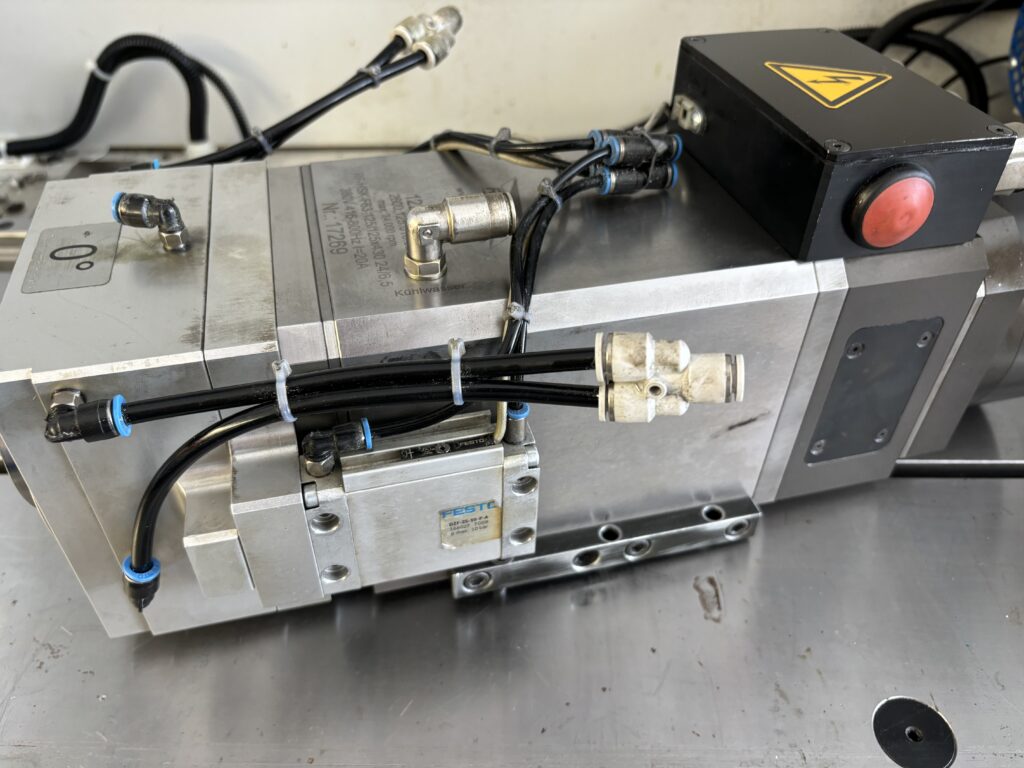

RECKERTH electrospindle regeneration

Key Features of the Reckert 122162201 Electric Spindle: Power and Efficiency: The electric spindle reaches speeds of up to 24,000 rpm, which allows for fast and precise machining of even the largest materials.

Versatility: provides the system with local RF-HSK-F63, the electric spindle is with a wide range of machining tools, which increases the depth of production.

Power Supply: 380 V and 416-800 Hz power supply ensures stable operation in all conditions.

Cooling Efficiency: Integrated dissipation system (Kühlwasser) effectively dissipates heat, supplies power and devices.

Solid Construction: The electric spindle is made of high-quality materials, which ensures that damage will occur even in the most demanding conditions.

Comprehensive Regeneration of the Reckert 122162201 Electrospindle In our service, we carried out a comprehensive regeneration of the Reckert 122162201 electrospindle to ensure its maximum efficiency and reliability. Thanks to our experience and advanced technologies, the device was restored to almost factory condition, ready for further, trouble-free operation.

Scope of work carried out:

Bearing replacement: New, high-quality bearings were used, which ensure smooth and quiet operation of the electrospindle, increasing its service life.

Cone check: The cone of the electrospindle was thoroughly checked and refined to ensure maximum precision in the machining process.

Component inspection and replacement: All key elements of the electrospindle, including seals and cables, were checked and replaced if necessary to ensure full functionality of the device.

Balancing and running-in: The electrospindle was precisely balanced and run-in, which eliminates vibrations and ensures stable operation even at the highest speeds.

Ready to work at the customer’s:

Thanks to the regeneration, the Reckert 122162201 electrospindle is fully prepared for operation. After installation in the CNC machine, it will be immediately ready for operation, without the need for additional calibration or adjustment. This is an ideal solution for companies that value reliability and want to minimize downtime.Trust professional regeneration:

Our regeneration service is a guarantee of quality and durability. Thanks to the use of modern methods and rigorous control procedures, the electrospindle regenerated by us will serve for a long time, maintaining all factory parameters.