Professional Overhaul, Bearing Replacement, and Taper Repair

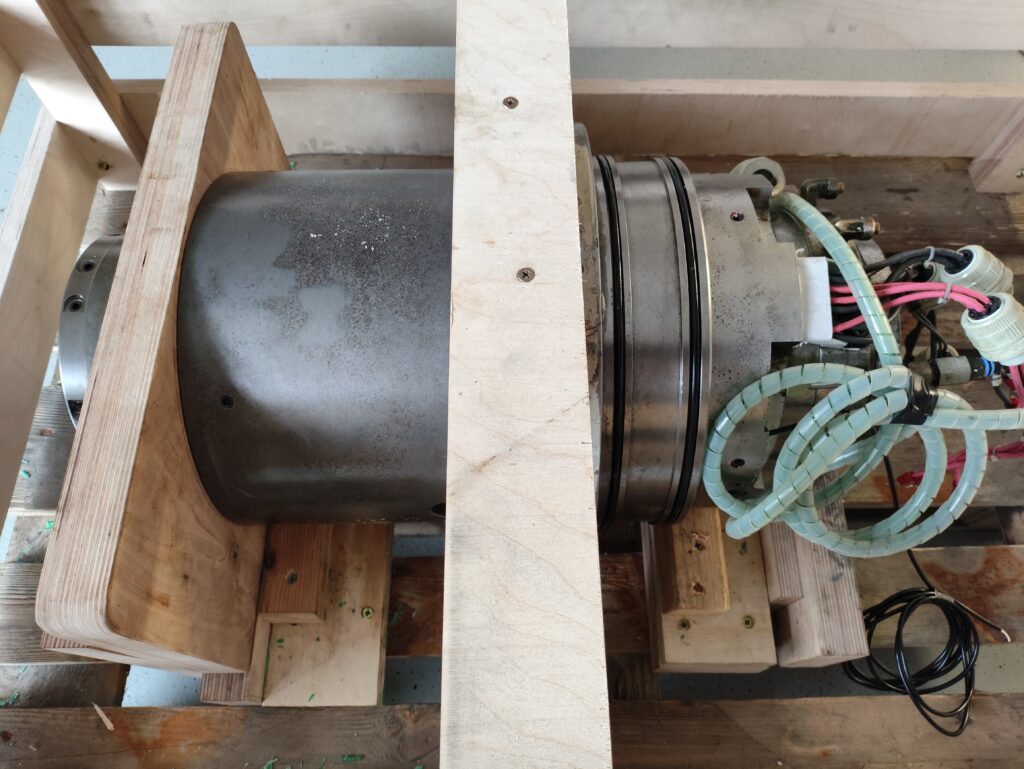

The photo shows a spindle from a Mazak HT5000 machining center, reaching a rotational speed of 12,000 rpm. This high-performance spindle is used in advanced precision machining applications that demand maximum accuracy, rigidity, and stability.

The presented spindle comes from a Lithuanian manufacturing facility, which entrusted FUMAK with a complete service and regeneration. This is yet another proof that Polish precision and FUMAK’s expertise are recognized and appreciated not only in Poland but throughout Europe.

Mazak Spindle Bearing Replacement – Precision and Durability

During the regeneration process, a complete bearing replacement was performed using high-grade precision bearings from reputable manufacturers.

The process included:

- disassembly and thorough cleaning of the housing and drive components,

- measurement of raceways, bores, and spindle shaft wear,

- installation of new bearings with factory-specified clearances and torque values,

- dynamic rotor balancing to accuracy class G1.0,

- final high-speed testing and temperature monitoring.

As a result, the spindle regains full operational performance, smooth running, and durability comparable to a brand-new unit.

Spindle Taper Reconditioning – Perfect Tool Clamping Accuracy

In many cases, poor machining quality results not only from worn bearings but also from taper runout or wear. At FUMAK, we perform Mazak spindle taper reconditioning, restoring its original geometry and coaxial alignment with the shaft.

Our process includes:

- precision grinding of HSK / BT / ISO tapers,

- coaxiality inspection on precision measuring systems,

- runout and ovality testing,

- restoring parameters according to OEM standards.

Through taper regeneration, we achieve perfect tool clamping, ensuring higher machining accuracy and extending the spindle’s overall service life.

Why Choose FUMAK?

For years, FUMAK has specialized in CNC spindle repair and overhaul – including brands such as Mazak, DMG Mori, Heller, Okuma, Haas, Fanuc, and Kessler.

Our technical facilities and experienced engineers allow us to handle even the most demanding repairs.

By choosing FUMAK, you benefit from:

- professional damage diagnostics,

- short turnaround times,

- detailed post-repair measurement reports,

- warranty on all performed services,

- full assurance that your spindle will return to production in top condition.

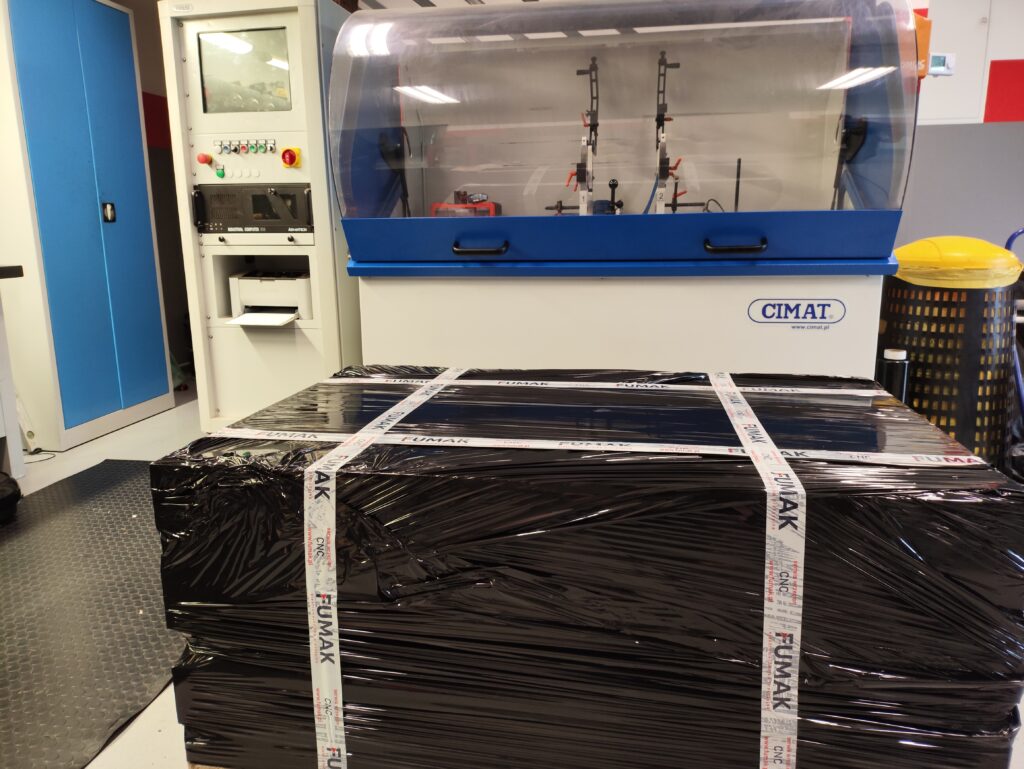

FUMAK – The Leading Spindle Service in Poland, Recognized Across Europe

If your spindle requires overhaul, bearing replacement, or taper repair – trust the FUMAK specialists.

We repair and regenerate spindles for manufacturing companies and service providers throughout Europe – from Poland to Lithuania, Germany, the Czech Republic, and Scandinavia.

📞 Contact us today and discover why so many European CNC manufacturers trust FUMAK for their spindle repairs.