1. Reception and Registration

- The spindle is received either directly from the customer or via courier shipment.

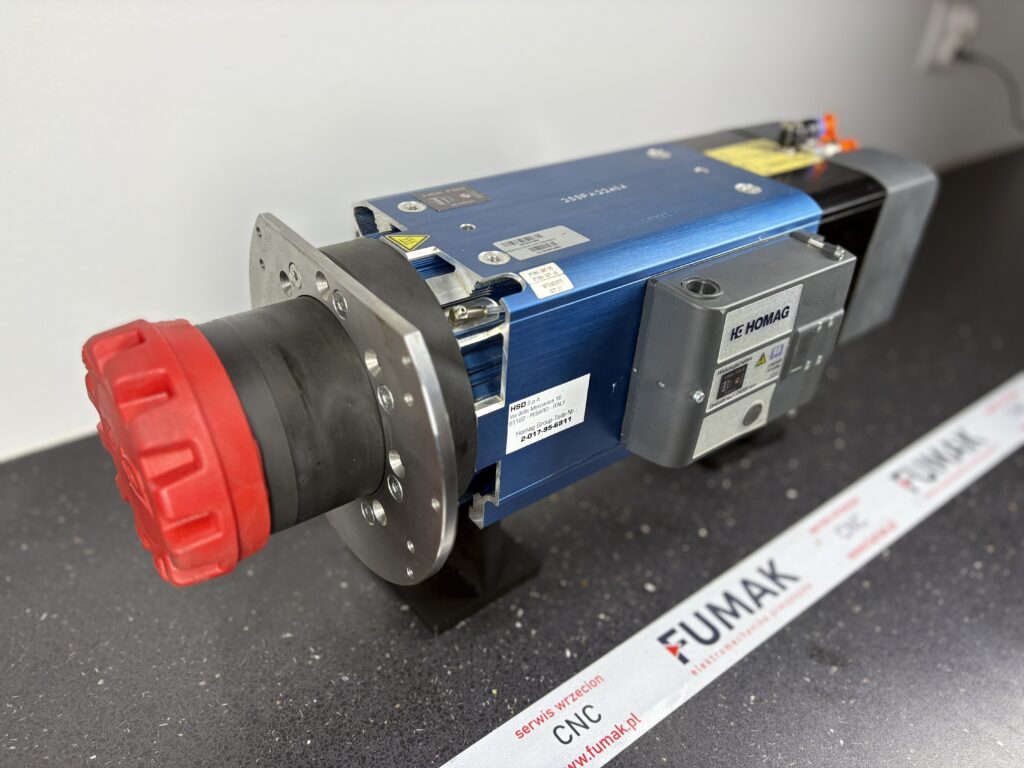

- The order is registered in our system — including customer data, spindle model and serial number, taper type (HSK F63), maximum speed (24,000 RPM), and reported symptoms.

- An initial visual inspection is performed to check for external damage, overheating marks, contamination, or leaks.

- High-resolution “before” photos are taken and stored in the service file for documentation and comparison after repair.

2. Initial Diagnostics (Before Disassembly)

- The spindle is connected to a test bench and briefly run under no-load conditions.

During this phase we record:- Sound and noise behavior (unusual vibration, knocking, whine),

- Vibration levels,

- Temperature rise (via infrared thermometer or thermal camera),

- Electrical current and resistance readings.

- Electrical tests include:

- Winding resistance and insulation measurement (megger test),

- Current draw across different RPM levels,

- Basic vibration analysis (axes X/Y/Z at several speeds).

- A preliminary diagnostic report is created with recommendations — e.g. bearing replacement, rewinding, cooling system repair.

3. Disassembly and Documentation

- Each component is carefully marked for reassembly alignment and orientation.

- External covers, toolholders, and cooling lines are removed.

- The spindle is extracted from its housing using lifting tools to prevent damage to taper surfaces or bearing seats.

- Each stage of disassembly is photographed and recorded, including part numbers and observations.

4. Cleaning and Surface Preparation

- Rough cleaning — removal of chips, dirt, and excess grease.

- Precision cleaning using ultrasonic baths or approved solvents, ensuring material compatibility (especially important for spindles with internal cooling circuits).

- Drying and surface inspection for scratches, wear, or corrosion.

5. Detailed Inspection and Measurement

- Geometrical checks:

- Taper runout (radial and axial),

- Concentricity and straightness of the shaft,

- Bearing seat clearance and axial play.

- Non-destructive testing (NDT):

- Magnetic or dye-penetrant inspection if cracks are suspected.

- Bearing analysis:

- Condition of rolling elements, races, cages, signs of discoloration or overheating.

- Electrical inspection:

- Winding insulation and resistance, lead condition, stator core inspection.

- Cooling system check:

- Integrity of channels, seals, and connectors.

6. Service Decision and Cost Estimate

- Based on diagnostic results, a detailed quotation is prepared, listing all replacement parts and recommended operations.

- The customer reviews and approves the repair scope — we also offer “Basic” and “Premium” regeneration packages with different warranty terms.

7. Bearing Replacement and Mechanical Restoration

- Removal of old bearings using specialized tools and presses.

- Inspection and, if necessary, re-machining or regrinding of bearing seats to restore precision fits.

- Installation of new high-precision bearings (from top manufacturers) using controlled heating or pressing procedures.

- Replacement of seals, O-rings, spacers, and cooling components.

- Greasing or oil lubrication according to manufacturer recommendations and bearing specifications.

8. Electrical Rewinding and Component Repair (If Required)

- Rewinding of stator or rotor coils using high-grade materials and precise winding patterns.

- Replacement of internal cooling lines, thermistors, and connectors as needed.

- Post-repair electrical tests: resistance, insulation, and dielectric strength measurements.

9. Assembly and Preliminary Adjustment

- The spindle is reassembled following original markings and torque specifications.

- Bearing preload and axial clearances are set according to manufacturer tolerances.

- Rotational smoothness is checked manually before proceeding.

10. Dynamic Balancing

- The spindle undergoes both static and dynamic balancing using a precision balancing machine.

- Balancing is performed in one or multiple planes depending on design, reaching accuracy levels compliant with ISO G-class standards.

- All results are documented and attached to the final report.

11. Performance and Load Testing

- No-load testing: The spindle is run through its full speed range (up to 24,000 RPM) while monitoring:

- Vibration levels,

- Temperature rise,

- Electrical parameters (current, voltage, phase balance).

- Load simulation: In certain cases, we apply a controlled load to simulate cutting forces.

- Thermal monitoring: Temperatures of bearings and windings are continuously recorded.

- FFT vibration analysis: Frequency spectrum is analyzed to identify harmonics or potential resonance.

- Tool interface repeatability test: Ensures precise taper positioning and clamping consistency.

12. Final Quality Control

- Comparison of all key parameters with manufacturer specifications.

- Final measurements of runout, vibration, current, and temperature.

- Preparation of complete measurement documentation: before/after results, charts, and photos.

- Issuing a FUMAK Quality Certificate and detailed service report.

13. Packing and Shipping

- All critical surfaces (taper, shaft ends) are protected with covers and anti-corrosion films.

- The spindle is packed in a secure wooden crate or reinforced carton with anti-shock filling.

- Documentation included:

- Service report,

- Measurement certificates,

- Warranty card,

- Handling instructions.

- Shipment is arranged by FUMAK or the customer’s logistics partner.

14. Warranty and After-Sales Support

- All FUMAK spindle regenerations include a written warranty covering both labor and parts.

- Post-service support:

- Technical consultation via phone or online,

- On-site inspection (if needed),

- Preventive maintenance recommendations.

- Customers receive suggestions for maintenance intervals and condition monitoring best practices.

15. Optional Services

- Cooling system modernization or additional temperature sensors.

- Foto report of the entire repair process.

16. How to Prepare a Spindle for Shipment

- Disconnect the machine from power.

- Secure the tool taper to prevent movement.

- Clean external surfaces of coolant and chips.

- Pack the spindle securely in a padded box or crate.

- Include a note describing symptoms, visible damage, and contact details.

- Contact FUMAK before shipping — we will provide full transport instructions.

17. FAQ — Common Customer Questions

Do you only replace bearings?

Not necessarily — bearing replacement is just one step in a complete regeneration process. The full scope is determined after diagnostic testing.

Will the spindle perform like new?

Our goal is to restore the spindle’s precision and performance to factory-level parameters within allowable tolerances. In some cases, if major damage is found, certain components may be replaced entirely.

Do I receive a report?

Yes — each spindle repair comes with a detailed before and after report including measurements, vibration graphs, and high-resolution photos.